1070 aluminium coiled tube

Inqubo yokwelapha ukushisa engu-1070

ukucima uwoyela nokuthambisa.Amandla alolu hlobo lwentambo yensimbi awalungile njengaleyo yocingo lwensimbi olulaphelwe ngomthofu, kodwa izakhiwo ziyafana futhi nezindleko ziphansi.Ngemuva kokwakhiwa kwe-cold roll, ukucindezeleka kuyasuswa.Donsela kusayizi oshiwo, bese u-anneal.Izakhiwo zemishini yekhoyili ethambile ingatholakala kuphela ngemva kokucisha nokushisa ekushiseni okuphakathi.

Izimpawu kanye nezicelo ze-1070

Inezici ze-plasticity ephezulu, ukumelana nokugqwala, ukuqhutshwa kahle kwe-conductivity kanye ne-thermal conductivity, kodwa amandla aphansi, angaqiniswa ukwelashwa okushisa, ukungasebenzi kahle kwemishini, futhi angamukela ukushisela othintana naye kanye nokushisela igesi.Sebenzisa kakhulu izinzuzo zayo ukuze wenze izingxenye ezithile zesakhiwo ngokusebenza okuqondile, njenge-aluminium foil eyenziwe nge-gasket ne-capacitor, inetha yokuhlukanisa ishubhu ye-electron, intambo, ikhava yokuvikela ikhebula, inethi, umgogodla wezintambo kanye nezingxenye zesistimu yokungenisa umoya yendiza nezingxenye zokuhlobisa.

Imininingwane

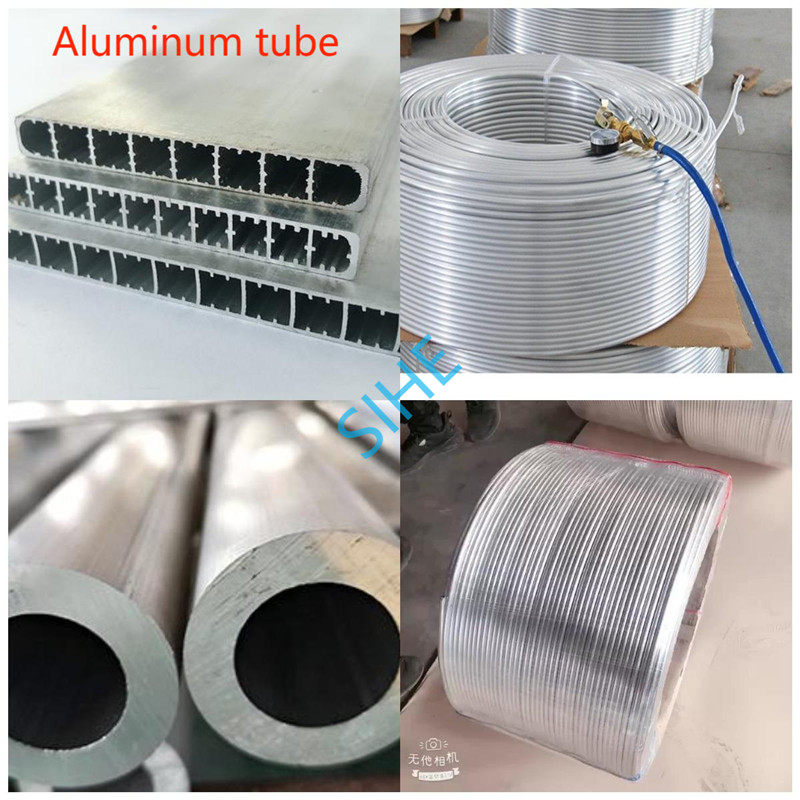

Ukucaciswa Okujwayelekile kwe-Aluminium tube

| Ingxubevange Cha. | Ulaka | I-Straight Tube | I-LWC | ||

| I-OD(mm) | I-WT(mm) | I-OD(mm) | I-WT | ||

| 1060(L2) | I-R(H112) | 6-30 | 0.6~3 | 4~22 | 0.2~2 |

| M(O) | 6-30 | 0.6~3 | 4~22 | 0.2~2 | |

| H 14 | 6-30 | 0.6~3 | 4~22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6-30 | 0.6~3 | 4~22 | 0.2~2 |

| H12 | 6-30 | 0.6~3 | 4~22 | 0.2~2 | |

| H14 | 6-30 | 0.6~3 | 4~22 | 0.2~2 | |

| H18 | 6-30 | 0.6~3 | 4~22 | 0.2~2 | |

| 6063 (LD31) | M(O) | 6-30 | 0.6~3 | 4~22 | 0.5~2 |

| T4 | 6-30 | 0.6~3 | 4~22 | 0.5~2 | |

| T6 | 6-30 | 0.6~3 | 4~22 | 0.5~2 | |

Ukucaciswa kwe-Inner Groove Aluminium Tube(Usayizi ungenziwa ngokwezifiso)

| Ukucaciswa(mm) | Ubukhulu bodonga(mm) | Ukuphakama Okuhlanganisiwe(mm) | I-Helical angle(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Izici Zemishini Ye-Inner Aluminium Grooved Tube

| Okubalulekile | I-tensile | I-Elongation Rate | Ukwandisa Isilinganiso |

| 3003 | 130MPA | 35 | 40 |

Ukucaciswa Kwekhoyili Yephakheji

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Ukuqina Kwezindonga | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

i-quanlity gurantee

1) ukubukeka kwangaphandle: indawo ehlanzekile eyisicaba ayikho yonke, iklwebhe, ingcolile kawoyela noma i-oxidation.

2) onqenqemeni lokusika: unqenqema lokusika oluhlanzekile alukho ama-burrs.

3) Umgomo wekhwalithi: izinga elifanelekile lokuhlolwa komkhiqizo ngu-98%.Ukwaneliseka kwamakhasimende ngama-95%.Material: A1050, A1060, A1070, A3003, nokunye

| I-A1050 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Abanye |

| 99.5 ~ 100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| I-A1060 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Abanye |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| I-A1070 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Abanye |

| 99.7-100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| I-A3003 Aluminium Chemical Composition | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Abanye Abangashadile | |

| abanye | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Ingxubevange | Ulaka | Ukucaciswa | |||

| Ubukhulu(mm) | Ububanzi(mm) | Amandla aqinile | Ukuqina | ||

| 7075 7005(ithubhu) | T5,T6,T9 | >0.5 | 5.0-80 | > 310 Mpa | > 140 |

| 6061 6063(amaphrofayili) | T5, T6 | >1.6 | 10-180 | > 572 MPA | I-HB90-110 |

| Ubude: < 6Meter | |||||

| TEMPER | UBUDILI(mm) | AMANDLA OKUQHUBEKA | ELONGATION% | Okujwayelekile |

| T5 | 0.4-5 | 60-100 | ≥ 20 | I-GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

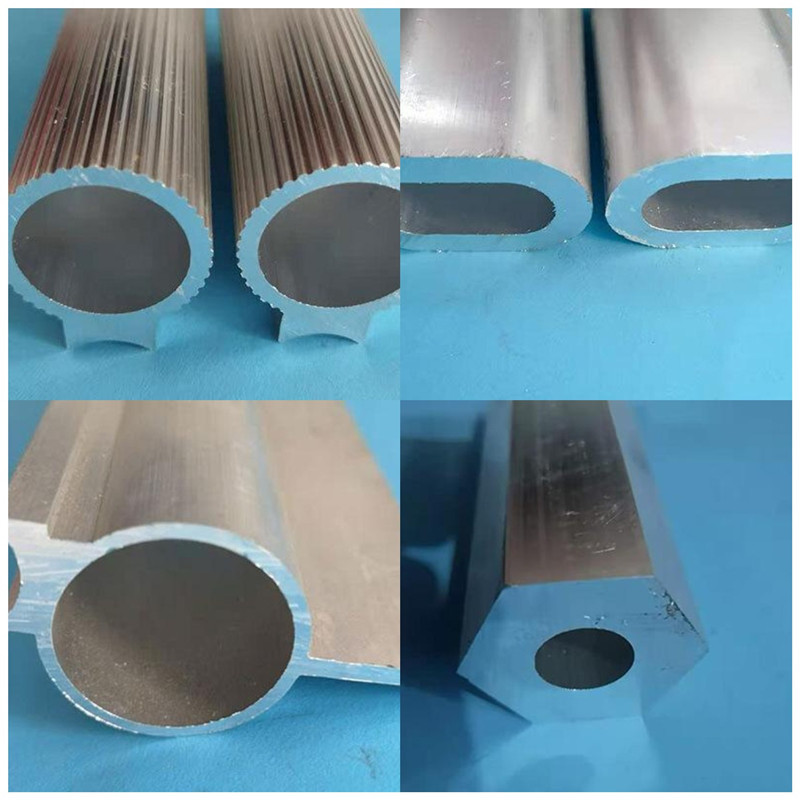

Umkhiqizo we-Aluminium