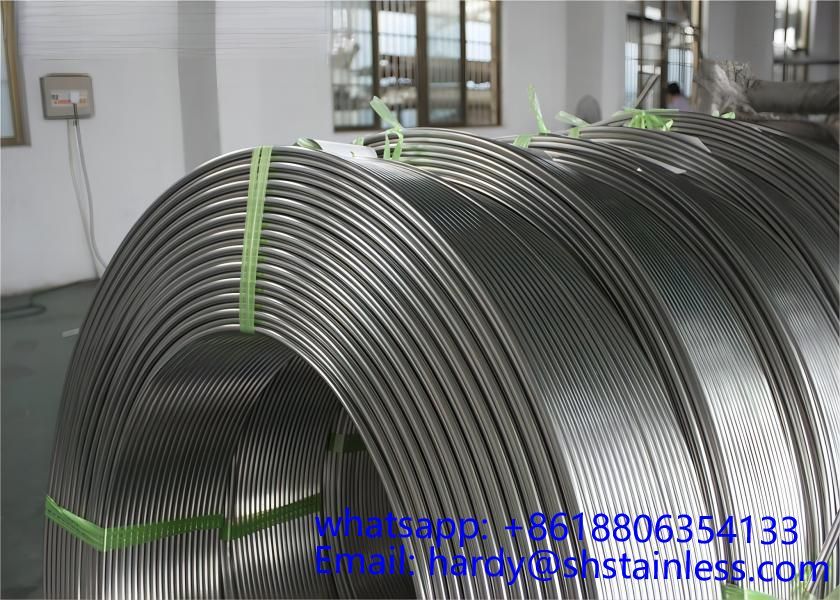

321L insimbi engagqwali 8 * 1mm amashubhu ahlanganisiwe

321 Insimbi Engagqwali

Leli shidi ledatha lisebenza kunsimbi engagqwali 321 / 1.4541 ishidi eligoqiwe elishisayo nelibandayo, imikhiqizo eseqediwe kancane, amabha, izintambo ezigoqiwe namaphrofayili kanye namashubhu angenamthungo nashikelwe ngezinhloso zokucindezela.

321L insimbi engagqwali 8 * 1mm amashubhu ahlanganisiwe

1.4541

Isicelo

Amathuluzi nezingxenye zokwakha embonini yokudla, ukudla okunethezeka, imboni yefilimu nezithombe kanye nemibhalo esetshenziswa nsuku zonke ekhaya, ukwakhiwa kwesiteshi sikagesi.Ngenxa ye-Ti-alloy, ukumelana nokugqwala kwe-intergranular nakho kuqinisekisiwe esimweni esishiselwe.

321L insimbi engagqwali 8 * 1mm amashubhu ahlanganisiwe

Ukwakhiwa Kwamakhemikhali

| Isici | % Okwamanje (ngefomu lomkhiqizo) | |||

|---|---|---|---|---|

| C, H, P | L | TW | TS | |

| Ikhabhoni (C) | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.08 |

| I-silicon (Si) | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 |

| I-Manganese (Mn) | ≤2.00 | ≤2.00 | ≤2.00 | ≤2.00 |

| I-Phosphorous (P) | ≤0.045 | ≤0.045 | ≤0.0453) | ≤0.040 |

| Isibabule (S) | ≤0.0151) | ≤0.0301) | ≤0.0153) | ≤0.0151) |

| I-Chromium (Cr) | 17.00 - 19.00 | 17.00 - 19.00 | 17.00 - 19.00 | 17.00 - 19.00 |

| I-Nickel (Ni) | 9.00 - 12.00 | 9.00 - 12.002) | 9.00 - 12.00 | 9.00 - 12.002) |

| I-Titanium (Ti) | 5xC kuya ku-0.70 | 5xC kuya ku-0.70 | 5xC kuya ku-0.70 | 5xC kuya ku-0.70 |

| Insimbi (Fe) | Ibhalansi | Ibhalansi | Ibhalansi | Ibhalansi |

321L insimbi engagqwali 8 * 1mm amashubhu ahlanganisiwe

Izakhiwo zemishini (emazingeni okushisa asekamelweni esimweni esishubile)

| Ifomu Lomkhiqizo | Ubukhulu obukhulu (mm) | Isivuno Amandla | Amandla Okuqina | Elongation min.nge-% | Amandla Anomthelela (ISO-V) ≥ 10mm ubukhulu | |||

|---|---|---|---|---|---|---|---|---|

| 0.2% Rp0.2 N/mm2 | 1% Rp1.0 N/mm2 | Rm N/mm2 | A1) %min (longitudinal) | A1) %min (okuphambene) | U-Jmin (longitudinal) | U-Jmin (transverse) | ||

| C | 8 | 2203) | 2203) | 520-7203) | - | 40 | - | - |

| H | 13.5 | 2003) | 2403) | 520-7203) | - | 40 | 100 | 60 |

| P | 75 | 2003) | 2403) | 500-7003) | - | 40 | 100 | 60 |

| L | 160 | 1904) | 2254) | 500-7004) | 40 | - | 100 | - |

| L | 2502) | 1907) | 2257) | 500-7007) | - | 30 | - | 60 |

| TW | 60 | 1805) | 2155) | 460-6805) | 35 | 30 | 100 | 60 |

| TS | 60 | 1805) | 2155) | 460-6805) | 35 | 30 | 100 | 60 |

321L insimbi engagqwali 8 * 1mm amashubhu ahlanganisiwe

Idatha yesithenjwa kwezinye izakhiwo ezibonakalayo

| Ukuminyana ku-20°C kg/m3 | 7.9 | |

|---|---|---|

| I-Modulus ye-Elasticity kN/mm2 ku- | 20°C | 200 |

| 200°C | 186 | |

| 400°C | 172 | |

| 500°C | 165 | |

| I-Thermal Conductivity W/m K ku-20°C | 15 | |

| Amandla Akhethekile Okushisa ku-20°CJ/kg K | 500 | |

| Ukumelana Nogesi ku-20°C Ω mm2/m | 0.73 | |

321L insimbi engagqwali 8 * 1mm amashubhu ahlanganisiwe

I-coefficient yomugqa wokunweba okushisayo okungu-10-6 K-1 phakathi kuka-20°C no

| 100°C | 16.0 |

|---|---|

| 200°C | 16.5 |

| 300°C | 17.0 |

| 400°C | 17.5 |

| 500°C | 18.0 |

Bhala umyalezo wakho lapha futhi usithumelele wona