I-alloy 600 I-Stainless Steel Coil Tubing Price

Ukwakheka Kwekhemikhali, %

Izicelo zokugqwala ezijwayelekile zifaka ukukhiqizwa kwe-titanium dioxide (umzila we-chloride), ama-perchlorethylene syntheses, i-vinyl chloride monomer (VCM), ne-magnesium chloride.I-alloy 600 isetshenziswa ekwenziweni nasekugcinweni kwamakhemikhali nokudla, ukwelapha ukushisa, ama-phenol condensers, ukwenziwa kwensipho, izitsha zemifino ne-fatty acid nokunye okuningi.

| I-Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 imiz | 14.0-17.0 | 6.0-10.0 | .15 ubuningi | 1.00 ubuningi | .015 ubuningi | .50 ubuningi | .50 ubuningi |

I-Inconel 600 isetshenziswa kuziphi izinhlelo zokusebenza?

- Imboni yamakhemikhali

- I-Aerospace

- Imboni yokwelapha ukushisa

- Imboni ye-Pulp nephepha

- Ukucubungula ukudla

- Ubunjiniyela Benuzi

- Izingxenye ze-turbine yegesi

Imininingwane ye-ASTM

| Ipayipi Smls | Ipayipi Elishiselwe | Amashubhu Smls | I-Tube Welded | Ishidi/Ipuleti | Indawo yokuphuzela utshwala | Ukuqamba | Iyalingana | Intambo |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Izakhiwo Zemishini

Izinga lokushisa elijwayelekile legumbi I-Tensile Properties of Annealed Material

| Ifomu Lomkhiqizo | Isimo | I-Tensile (ksi) | .2% Isivuno (ksi) | Ubude (%) | Ukuqina (HRB) |

| Induku & Ibha | Ebandayo | 80-100 | 25-50 | 35-55 | 65-85 |

| Induku & Ibha | Okushisayo-Kuqedile | 80-100 | 30-50 | 35-55 | 65-85 |

| Ipayipi & Ipayipi | Okushisayo-Kuqedile | 75-100 | 25-50 | 35*55 | - |

| Ipayipi & Ipayipi | Ebandayo | 80-100 | 25-50 | 35-55 | 88 Max |

| Ipuleti | I-Hot-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Ishidi | Ebandayo | 80-100 | 30-45 | 35-55 | 88 Max |

I-Inconel 600 Melting Point

| Isici | Ukuminyana | I-Melting Point | Amandla Okuqina | Amandla Esivuno (0.2%Offset) | Ukwelula |

| Ingxubevange 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

I-Inconel 600 Equivalent

| IZINGA | I-WERKSTOFF NR. | I-UNS | I-JIS | BS | I-GOST | AFNOR | EN |

| Ingxubevange 600 | 2.4816 | N06600 | I-NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | I-NC15FE11M | I-NiCr15Fe |

Ingxubevange 600 Tubing

I-alloy 600 iyikhandidethi elihle kakhulu ekusetshenzisweni okuningi kumazinga okushisa aphezulu kakhulu nasezindaweni ezigqwalile kakhulu.Inhlanganisela ye-nickel ne-chromium ikhiqiza ukumelana okuqinile ne-oxidation emazingeni okushisa okusebenza.Lawa mazinga okushisa angasukela ku-cryogenic kuya kumazinga ashisayo angu-2,000°F.Okuqukethwe okuphezulu kwe-nickel ye-alloy 400 nakho kunikeza ukumelana cishe okuphelele nokucindezeleka kokuqhekeka kokugqwala, okuvame ukutholakala ezindaweni ze-chloride.

Kubalulekile ukuqaphela ukuthi ingxenye ye-chromium yephrofayili yamakhemikhali engxubevange yenza kube nokwenzeka ukuthi izinga likwazi ukumelana namazinga okushisa aphezulu.Ukwakheka okusanhlamvu okucolisekileyo kweshubhu eliqediwe elibandayo, ngaphezu kwalokho, kuletha ukumelana nokugqwala okungcono, okuhlanganisa ukukhathala okuphezulu kanye namanani amandla okuthonya.

Imininingwane Yomkhiqizo

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Ububanzi besayizi

| Ngaphandle Ububanzi (OD) | Ukuqina Kwezindonga |

| .250”–.750” | .035”–.083” |

Izidingo Chemical

I-alloy 600 (UNS N06600)

Ukwakhiwa %

| Ni I-Nickel | Cu Ithusi | Fe Insimbi | Mn IManganese | C Ikhabhoni | Si I-silicon | S Isibabule | Cr I-Chromium |

| 72.0 imiz | 0.50 ubuningi | 6.00–10.00 | 1.00 ubuningi | 0.15 ubuningi | 0.50 ubuningi | 0.015 ubuningi | 14.0–17.0 |

I-Dimensional Tolerances

| OD | OD Ukubekezelelana | Ukubekezelelana Kwezindonga |

| ≤ .500” ngaphandle | +.005” | ± 12.5% |

| .500”–.750” ngaphandle | +.005” | ± 12.5% |

Izakhiwo Zemishini

| Amandla Okukhiqiza: | 35 ksi imiz |

| Amandla Okuqina: | 80 nxa |

| Ubude (min 2"): | 30% |

Ukwenziwa

I-alloy 600 ingashiswa kalula ngenqubo evamile.Ukuphathwa kwalesi singxubevange kuhle kakhulu, kuhlala phakathi kokusetshenziswa kwe-T303 ne-T304.

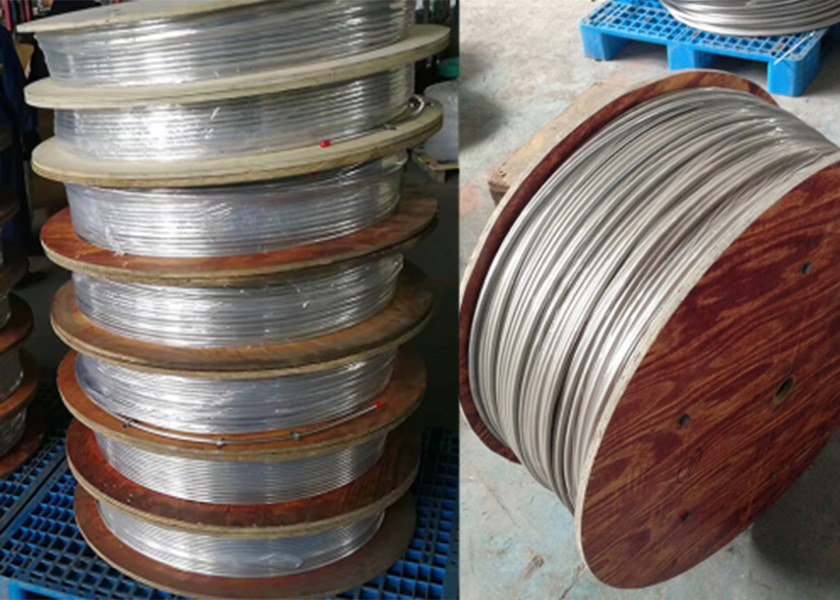

Izithombe zefekthri

Ukuhlola

Ukuthumela nokupakisha

Umbiko Wokuhlola