Lapho kwakhiwa kufa okuqhubekayo, ingcindezi ye-workpiece, izimo zokucindezela kanye nezinto zokuqala zithinta ikhono lokuthola imiphumela yokudweba ezinzile ngaphandle kwemibimbi.

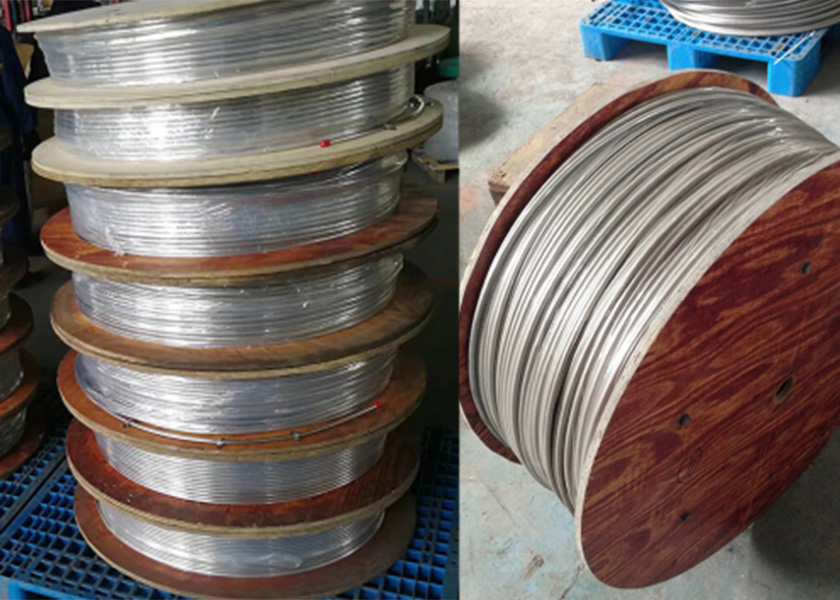

Q: Senza inkomishi ngensimbi engagqwali engu-304.Esiteshini sokuqala sokufa okuqhubekayo, sidonsa cishe ngamasentimitha angu-0.75 ukujula.Uma ngibheka ukujiya komngcele we-butt flange, kungahluka ngamayintshi angu-0.003 ukusuka kolunye uhlangothi kuya kolunye.Ukushaywa ngakunye kuhlukile futhi akuveli endaweni efanayo.Ngatshelwa ukuthi ihlobene nokucutshungulwa kwempahla eluhlaza, mhlawumbe unqenqema lwangaphandle lwe-spool enkulu.Singayithola kanjani inkomishi emile njalo ngaphandle kwama-creases?

IMPENDULO: Ngiyabona ukuthi umbuzo wakho uphakamisa imibuzo emibili: okokuqala ukuhlukahluka okutholayo lapho udweba, futhi okwesibili into ewumthombo kanye nokucaciswa kwayo.

Inkinga yokuqala iyiphutha eliyisisekelo ekwakhiweni kwethuluzi, ngakho-ke ake sidlule ezintweni eziyisisekelo.Ukushwabana kwezikhathi ezithile nokuguquguquka kogqinsi kuma-flange enkomishi ngemva kokwelula kubonisa amathuluzi esibopho anganele esiteshini sakho esiqhubekayo sokwelula.Ngaphandle kokubona idizayini yakho yokufa, kuzofanela ngicabange ukuthi i-punch ne-die radii kanye nokucaciswa kwayo okuhambisanayo kuhlangabezana nayo yonke imingcele yedizayini evamile.

Ngesikhathi senqubo yokudweba, i-workpiece ibanjwe phakathi komdwebo wokufa kanye nesibambi sonqenqema, kuyilapho i-punch yokudweba idonsa into efasiteleni lomdwebo, iyidonsa eduze kwendawo yokudweba ukuze yakhe igobolondo.Ukungqubuzana okuqinile kwenzeka phakathi kwesikhunta nesibambi somsebenzi.Phakathi nale nqubo, okubalulekile kungaphansi kokucindezelwa okuphambene, okuholela ekushwabaneni nasekunwetshweni kwe-radial njengoba umbambi wonqenqema emisa ukuhamba kwezinto.Uma ingcindezi yokuvala iphezulu kakhulu, impahla izophuka ngaphansi kwamandla okudonsa we-punch.Uma liphansi kakhulu, kuzovela imibimbi.

Umsebenzi ophumelelayo wokudweba awukwazi ukudlula umkhawulo phakathi kobubanzi begobolondo kanye nobubanzi be-workpiece.Lo mkhawulo uncike emaphesentini wobude bento.Umthetho ojwayelekile uwukupenda u-55% kuya ku-60% okokuqala no-20% isikhathi ngasinye ngemuva kwalokho.Emkhiwaneni.I-1 ibonisa ifomula evamile yokubala ingcindezi ye-preform edingekayo ukuze kunwetshwe (ngihlala ngengeza okungenani amandla engeziwe angu-30% njengesici sokuphepha. Lokhu kungancishiswa uma kunesidingo, kodwa kunzima ukwandisa ngemva kokuqedwa komklamo).

I-billet pressure p ingu-2.5 N/mm2 yensimbi, 2.0-2.4 N/mm2 yealloy yethusi kanye no-1.2-1.5 N/mm2 ye-aluminium alloy.

Umehluko ekujikeni kwe-flange kungaphinda kubonise ukuthi ukwakheka kwethuluzi lakho akuqinile ngokwanele.Isicathulo sesikhunta kufanele sibe ukuqina ngokwanele ukumelana nokushuba ngaphandle kokugoba.Ukusekela ngaphansi kwesicathulo kufanele kube yinsimbi eqinile, futhi izikhonkwane zomhlahlandlela zamathuluzi kufanele zibe zikhulu ngokwanele ukuvimbela ukunyakaza kwe-lateral kwamathuluzi angaphezulu naphansi ngesikhathi sokwelula.

Bheka futhi izindaba zakho.Uma iziqondiso zokushicilela zigugile futhi zixega, ngeke uphumelele, kungakhathaliseki ukuthi amathuluzi akho aqine kangakanani.Hlola i-press pusher ukuze uqiniseke ukuthi ilungile futhi isikwele kulo lonke ubude be-press stroke.Qinisekisa ukuthi okokugcoba kwakho kuhlungiwe futhi kusesimweni esihle, nokuthi ithuluzi lisebenzisa inani elifanele kanye nendawo elungile yombhobho.Wonke amathuluzi okuphrinta ahlolwe ngokucophelela ukuze kuqinisekiswe ukuqedwa kwendawo efanele, ukumbozwa kanye nokulinganisa.Futhi unake ngokukhethekile ukudweba i-radii, kumele babe ne-geometry ephelele kanye nokuhlanzeka kwendawo.

Futhi, ngenkathi amakhasimende evame ukucabanga ukuthi i-304L ne-304 ejwayelekile iyashintshana, i-304L iyisinqumo esingcono kakhulu sokwelula.L imele ikhabhoni ephansi, enikeza u-304L amandla okukhiqiza angu-0.2% angu-35 KSI, kuyilapho i-304 inamandla okukhiqiza angu-0.2% angu-42 KSI.Ngamandla okukhiqiza aphansi angu-16%, i-304L idinga amandla amancane ukuguqula nokubamba isikhunta ngesikhathi sokubumba.Kulula ukuyisebenzisa.

Are you concerned about stamping in the shop or about tools and dies? If so, send your questions to kateb@thefabricator.com and Thomas Vacca, CTO of Micro Co., will answer them.

STAMPING Journal ukuphela kwencwadi yezohwebo enikelwe kuphela izidingo zemakethe yokugxiviza ngensimbi.Kusukela ngo-1989, ukushicilelwa kunikezelwe kubuchwepheshe obuphambili, izitayela zemboni, izinqubo ezingcono kakhulu kanye nezindaba zokusiza ochwepheshe bokugxiviza baqhube ibhizinisi labo ngempumelelo kakhudlwana.

Ukufinyelela okugcwele kwedijithali ku-FABRICATOR manje kuyatholakala, okuhlinzeka ngokufinyelela okulula kwezinsiza ezibalulekile zemboni.

Ukufinyelela okugcwele kwedijithali ku-The Tube & Pipe Journal manje kuyatholakala, okuhlinzeka ngokufinyelela kalula kuzinsiza ezibalulekile zemboni.

Jabulela ukufinyelela okudijithali okugcwele ku-STAMPING Journal, ijenali yemakethe yezitembu zensimbi enentuthuko yakamuva yobuchwepheshe, imikhuba engcono kakhulu nezindaba zemboni.

Ukufinyelela okugcwele kuhlelo lwedijithali lwe-The Fabricator en Español manje sekuyatholakala, okuhlinzeka ngokufinyelela okulula kuzinsiza ezibalulekile zemboni.

Engxenyeni yokuqala yochungechunge lwethu olunezingxenye ezimbili, umdwebi wensimbi kanye nomshiseli uRay Ripple ujoyina umphathi uDan Davis…

Isikhathi sokuthumela: Jan-03-2023