I-Duplex Stainless Steel - Superduplex

Kwezokusansimbi, insimbi engagqwali iyingxubevange yensimbi okungenani ene-chromium engu-10.5% enezakhi ze-alloying noma ezingenazo kanye nenani eliphakeme le-carbon engu-1.2% ngobuningi.Izinsimbi ezingenasici, ezaziwa nangokuthi izinsimbi ze-inox noma i-inox evela ku-French inoxydable (inoxidizable),ama-alloys ensimbiezaziwa kakhulu ngokumelana nokugqwala, okwandayo ngokwanda kokuqukethwe kwe-chromium.Ukumelana nokubola kungase kuthuthukiswe nezengezo ze-nickel ne-molybdenum.Ukumelana nalawa ma-alloys ensimbi emiphumeleni yamakhemikhali yama-ejenti ezonakalisayo kusekelwe ku-passivation.Ukuze i-passivation yenzeke futhi ihlale izinzile, ingxubevange ye-Fe-Cr kufanele ibe nobuncane bokuqukethwe kwe-chromium okungaba ngu-10.5% ngesisindo, okungaphezu kwalokho okungenzeki futhi kungenzeki ngaphansi.I-Chromium ingasetshenziswa njengento eqinisayo futhi ivamise ukusetshenziswa nento eqinisayo njenge-nickel ukuze kukhiqizwe izici zomshini ezihamba phambili.

I-Duplex Stainless Steel

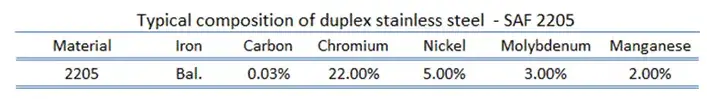

Njengoba igama labo libonisa, izinsimbi ezingenasici ze-Duplex ziyinhlanganisela yezinhlobo ezimbili eziyinhloko ze-alloy.Bane-microstructure exubile ye-austenite ne-ferrite, inhloso ngokuvamile ukukhiqiza ingxube engu-50/50, nakuba, kuma-alloys okuhweba, isilinganiso singase sibe ngu-40/60.Ukumelana nokugqwala kwabo kufana nozakwabo be-austenitic, kodwa ukumelana kwabo kwe-stress-corrosion (ikakhulukazi i-chloride stress corrosion cracking), amandla aqinile, namandla okukhiqiza (cishe amandla aphindwe kabili okukhiqiza ama-austenitic stainless steels) ngokuvamile aphakeme kunalawo e-austenitic. amabanga.Ensimbi engagqwali eyi-duplex, ikhabhoni igcinwa ifike kumazinga aphansi kakhulu (C<0.03%).Okuqukethwe kwe-Chromium kusuka ku-21.00 kuye ku-26.00%, okuqukethwe kwe-nickel kusuka ku-3.50 kuya ku-8.00%, futhi lawa ma-alloys angase aqukathe i-molybdenum (kufika ku-4.50%).Ukuqina kanye ne-ductility ngokuvamile kuwela phakathi kwalawo amamaki e-austenitic kanye ne-ferritic.Amamaki e-Duplex ngokuvamile ahlukaniswa abe ama-sub-groups amathathu ngokusekelwe ekuphikeleni ukugqwala kwawo: i-lean duplex, i-duplex evamile, ne-superduplex.Izinsimbi ze-Superduplex zikhulise amandla nokumelana nazo zonke izinhlobo zokugqwala uma kuqhathaniswa nezinsimbi ezijwayelekile ze-austenitic.Ukusetshenziswa okuvamile kufaka izicelo zasolwandle, izitshalo ze-petrochemical, izitshalo zokususa usawoti emanzini, izishintshisi zokushisa, kanye nemboni yokwenza amaphepha.Namuhla, imboni kawoyela negesi ingumsebenzisi omkhulu kunayo yonke futhi iphushele amamaki amaningi amelana nokugqwala, okuholela ekuthuthukisweni kwezinsimbi ze-superduplex.

Ukumelana nensimbi engagqwali emiphumeleni yamakhemikhali yama-ejenti e-corrosive kusekelwe ku-passivation.Ukuze i-passivation yenzeke futhi ihlale izinzile, ingxubevange ye-Fe-Cr kufanele ibe nobuncane bokuqukethwe kwe-chromium okungaba ngu-10.5% ngesisindo, okungaphezu kwalokho okungenzeki futhi kungenzeki ngaphansi.I-Chromium ingasetshenziswa njengento eqinisayo futhi ivamise ukusetshenziswa nento eqinisayo njenge-nickel ukuze kukhiqizwe izici zomshini ezihamba phambili.

I-Duplex Stainless Steels - SAF 2205 - 1.4462

Insimbi engagqwali eyi-duplex evamile i-SAF 2205 (uphawu lokuthengisa oluphethwe yi-Sandvik lwensimbi engagqwali engu-22Cr duplex (ferritic-austenitic), ngokuvamile equkethe u-22% we-chromium kanye ne-nickel engu-5%.Inokumelana nokugqwala okuhle kakhulu namandla aphezulu, i-2205 iyinsimbi engagqwali eyi-duplex esetshenziswa kakhulu.Izicelo ze-SAF 2205 zikulezi zimboni ezilandelayo:

- Ezokuthutha, ukugcinwa, kanye nokucubungula amakhemikhali

- Imishini yokucubungula

- I-chloride ephezulu nezindawo zasolwandle

- Ukuhlola uwoyela negesi

- Imishini yamaphepha

Izakhiwo ze-Duplex Stainless Steel

Izakhiwo zezinto ezibonakalayo ziyizakhiwo eziqinile, okusho ukuthi azizimele kumthamo wesisindo futhi zingahluka ezindaweni ngezindawo ngaphakathi kwesistimu nganoma yisiphi isikhathi.Isayensi yezinto ezibonakalayo ibandakanya ukutadisha ukwakheka kwezinto futhi zihlobanise nezakhiwo zazo (imishini, kagesi, njll.).Uma usosayensi wezinto ezisetshenziswayo azi mayelana nalokhu kuhlobana kwesakhiwo nesakhiwo, angakwazi ukuqhubeka nokufunda ukusebenza okuhlobene kokubalulekile kuhlelo lokusebenza olunikeziwe.Izinqumo ezinkulu zesakhiwo sempahla kanjalo nezakhiwo zayo yizakhi zayo zamakhemikhali eziyingxenye nokuthi icutshungulwe kanjani yaba yisimo sayo sokugcina.

Izakhiwo Zemishini Yensimbi Engagqwali ye-Duplex

Izinto ezisetshenziswayo zivame ukukhethelwa izinhlelo zokusebenza ezahlukahlukene ngenxa yokuthi zinenhlanganisela efiselekayo yezimpawu zemishini.Kuhlelo lokusebenza lwesakhiwo, izakhiwo zezinto ezibonakalayo zibalulekile futhi onjiniyela kufanele bazicabangele.

Amandla e-Duplex Stainless Steel

Kumakhenikha wezinto zokwakha, iamandla entoikhono layo lokumelana nomthwalo osetshenzisiwe ngaphandle kokwehluleka noma ukuguqulwa kwepulasitiki.Amandla ezinto ezisetshenziswayo acabangela ubudlelwano phakathi kwemithwalo yangaphandle esetshenziswa kokubalulekile kanye nomphumela wokuwohloka noma ukuguqulwa kobukhulu bezinto ezibonakalayo.Amandla ezinto ezibonakalayo yikhono layo lokumelana nalo mthwalo osetshenzisiwe ngaphandle kokwehluleka noma ukuguqulwa kwepulasitiki.

Amandla Okuqina Okugcina

Amandla okugcina ensimbi engagqwali eyi-duplex - SAF 2205 yi-620 MPa.

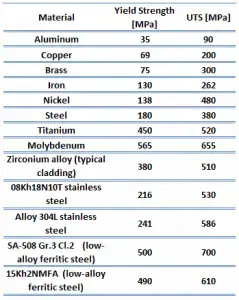

Iamandla okugcinaubuningi bobunjiniyelaijika le-stress-strain.Lokhu kuhambisana nokucindezelwa okukhulu okuqhubekayo kwesakhiwo esishubile.Amandla aqine kakhulu avame ukufushaniswa ukuze abe “amandla aqinile” noma “okugcina.”Uma lokhu kucindezeleka kusetshenziswa futhi kugcinwa, kuzovela ukuphuka.Ngokuvamile, leli nani lingaphezu kokucindezeleka kwesivuno (okungamaphesenti angama-50 kuya kwangu-60 ngaphezu kwesivuno sezinhlobo ezithile zezinsimbi).Uma i-ductile material ifinyelela emandleni ayo okugcina, ihlangabezana nentamo lapho indawo ye-cross-sectional inciphisa endaweni.Ijika le-stress-strain aliqukethe ingcindezi ephakeme kunamandla okugcina.Noma ama-deformation angaqhubeka nokukhula, ingcindezi ivamise ukwehla ngemva kokuthola amandla okugcina.Kuyimpahla ejulile;ngakho-ke, inani layo alincikile kusayizi wesampula yokuhlola.Kodwa-ke, kuncike kwezinye izici, njengokulungiselelwa kwesifanekiso, ukuba khona noma okunye ukonakala kwendawo, nezinga lokushisa lendawo yokuhlola nezinto ezibonakalayo.Amandla okuqina aphezulu ahluka ukusuka ku-MPa angama-50 ku-aluminium ukuya phezulu njengo-3000 MPa ngensimbi enamandla kakhulu.

Iamandla okugcinaubuningi bobunjiniyelaijika le-stress-strain.Lokhu kuhambisana nokucindezelwa okukhulu okuqhubekayo kwesakhiwo esishubile.Amandla aqine kakhulu avame ukufushaniswa ukuze abe “amandla aqinile” noma “okugcina.”Uma lokhu kucindezeleka kusetshenziswa futhi kugcinwa, kuzovela ukuphuka.Ngokuvamile, leli nani lingaphezu kokucindezeleka kwesivuno (okungamaphesenti angama-50 kuya kwangu-60 ngaphezu kwesivuno sezinhlobo ezithile zezinsimbi).Uma i-ductile material ifinyelela emandleni ayo okugcina, ihlangabezana nentamo lapho indawo ye-cross-sectional inciphisa endaweni.Ijika le-stress-strain aliqukethe ingcindezi ephakeme kunamandla okugcina.Noma ama-deformation angaqhubeka nokukhula, ingcindezi ivamise ukwehla ngemva kokuthola amandla okugcina.Kuyimpahla ejulile;ngakho-ke, inani layo alincikile kusayizi wesampula yokuhlola.Kodwa-ke, kuncike kwezinye izici, njengokulungiselelwa kwesifanekiso, ukuba khona noma okunye ukonakala kwendawo, nezinga lokushisa lendawo yokuhlola nezinto ezibonakalayo.Amandla okuqina aphezulu ahluka ukusuka ku-MPa angama-50 ku-aluminium ukuya phezulu njengo-3000 MPa ngensimbi enamandla kakhulu.

Isivuno Amandla

Amandla okukhiqiza we-duplex steel stainless - SAF 2205 yi-440 MPa.

Iisivuno iphuzuiphuzu ku-aijika le-stress-strainlokho kubonisa umkhawulo wokuziphatha okunwebekayo kanye nokuziphatha kokuqala kwepulasitiki.Amandla esivuno noma ukucindezeleka kokuvunwa yimpahla ebonakalayo echazwa njengengcindezi lapho okubalulekile kuqala ukonakala ngokwepulasitiki.Ngokuphambene, iphuzu lokukhiqiza liyiphuzu lapho ukuguqulwa kwe-nonlinear (elastic + plastic) kuqala.Ngaphambi kwephuzu lokukhiqiza, impahla izokhubaza ngokunwebeka futhi ibuyele esimweni sayo sokuqala lapho ukucindezeleka okusetshenzisiwe kususwa.Uma iphuzu lokukhiqiza selidlulile, ingxenye ethile ye-deformation izoba unomphela futhi ingabuyiseleki emuva.Ezinye izinsimbi nezinye izinto ezisetshenziswayo zibonisa indlela yokuziphatha ebizwa ngokuthi i-yield point phenomenon.Amandla esivuno ayahluka ukusuka ku-35 MPa ku-aluminium yamandla aphansi ukuya ku-1400 MPa ngensimbi enamandla amakhulu.

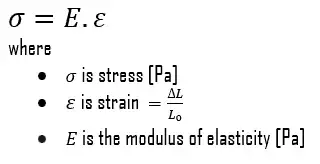

I-Young's Modulus of Elasticity

I-Young's modulus of elasticity of duplex stainless steel - SAF 2205 ingama-200 GPa.

I-modulus encane ye-elasticityi-elastic modulus ye-tensile ne-compressive state ku-linear elasticity regime ye-uniaxial deformation futhi ngokuvamile ihlolwa ngokuhlolwa okuqinile.Kuze kufike ekunciphiseni ingcindezi, umzimba uzokwazi ukubuyisela ubukhulu bawo ekukhishweni komthwalo.Izingcindezi ezisetshenzisiwe zenza ama-athomu akukristalu asuke endaweni yawo yokulinganisa, nakho konkeama-athomuziyasuswa inani elifanayo futhi zigcine i-geometry yazo ehlobene.Lapho izingcindezi zisusiwe, wonke ama-athomu abuyela ezindaweni zawo zakuqala, futhi akukho ukuguquguquka okuhlala njalo okwenzekayo.Ngokuvumelana neUmthetho kaHooke, ingcindezi ilingana nokucindezeleka (endaweni enwebekayo), futhi umthambeko uyimoduli ye-Young.I-modulus ye-Young ilingana nokucindezeleka kwe-longitudinal ehlukaniswe uhlobo.

Ukuqina kwe-Duplex Stainless Steel

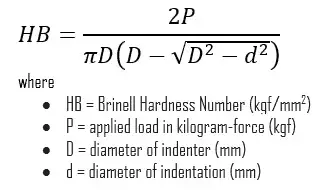

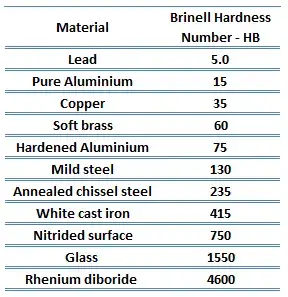

Ubulukhuni be-Brinell bensimbi engagqwali e-duplex - i-SAF 2205 cishe i-217 MPa.

Kwisayensi yezinto zokwakha,ubulukhuniyikhono lokumelana nokuhlehla phezulu (ukuguqulwa kwepulasitiki yendawo) kanye nokunwaya.Ukuqina cishe kuyimpahla engachazwa kahle kakhulu ngoba ingase ibonise ukumelana nokuklwebheka, ukuhuzuka, ukuhlehlisa, noma ukumelana nokubunjwa noma ukuguqulwa kwepulasitiki kwendawo.Ukuqina kubalulekile ngokombono wobunjiniyela ngoba ukumelana nokugugiswa noma ukuguguleka ngesitimu, uwoyela, namanzi ngokuvamile kuyenyuka ngobulukhuni.

Kwisayensi yezinto zokwakha,ubulukhuniyikhono lokumelana nokuhlehla phezulu (ukuguqulwa kwepulasitiki yendawo) kanye nokunwaya.Ukuqina cishe kuyimpahla engachazwa kahle kakhulu ngoba ingase ibonise ukumelana nokuklwebheka, ukuhuzuka, ukuhlehlisa, noma ukumelana nokubunjwa noma ukuguqulwa kwepulasitiki kwendawo.Ukuqina kubalulekile ngokombono wobunjiniyela ngoba ukumelana nokugugiswa noma ukuguguleka ngesitimu, uwoyela, namanzi ngokuvamile kuyenyuka ngobulukhuni.

Ukuhlolwa kokuqina kweBrinellingenye yokuhlola ubulukhuni be-indent eyenzelwe ukuhlola ubulukhuni.Ezivivinyweni ze-Brinell, i-indenter eqinile, eyindilinga iphoqelelwa ngaphansi komthwalo othize ebusweni bensimbi ukuze ihlolwe.Ukuhlola okuvamile kusebenzisa ibhola lensimbi eliqinile elingu-10 mm (0.39 in) ububanzi njenge-indenter enamandla angu-3,000 kgf (29.42 kN; 6,614 lbf).Umthwalo ugcinwa ungashintshi isikhathi esithile (phakathi kwe-10 ne-30 s).Ukuze uthole izinto ezithambile, kusetshenziswa amandla amancane;ngezinto eziqinile, ibhola le-tungsten carbide lithathelwa indawo yebhola lensimbi.

Ukuhlola kunikeza imiphumela yezinombolo ukuze kulinganise ubulukhuni bento, evezwa inombolo yobulukhuni be-Brinell - HB.Inombolo yobulukhuni be-Brinell iqokwe amazinga okuhlola avame ukusetshenziswa kakhulu (ASTM E10-14[2] kanye ne-ISO 6506–1:2005) njenge-HBW (H esuka kokuqina, B evela ku-Brinell, kanye no-W kusukela kumpahla ye-indenter, i-tungsten (wolfram) carbide).Ezilinganisweni zangaphambili, i-HB noma i-HBS yayisetshenziselwa ukubhekisela ezilinganisweni ezenziwe ngezikhombi zensimbi.

Inombolo yobulukhuni be-Brinell (HB) umthwalo ohlukaniswa ngendawo engaphezulu yokuhlehlisa.Ububanzi bombono bulinganiswa ngesibonakhulu esinesikali esibekwe phezulu.Inombolo yobulukhuni be-Brinell ibalwa kusukela kuzibalo:

Kunezindlela ezahlukahlukene zokuhlola ezisetshenziswa kakhulu (isb., Brinell,Knoop,Vickers, futhiRockwell).Kunamathebula atholakalayo ahlobanisa izinombolo zokuqina ezindleleni zokuhlola ezihlukene lapho kuhlotshaniswa khona.Kuzo zonke izikali, inombolo yokuqina okuphezulu imelela insimbi eqinile.

Izakhiwo ezishisayo ze-Duplex Stainless Steel

Izakhiwo ezishisayo zezinto zokwakha zibhekisela ekuphenduleni kwezinto ezishintshayo ekushintsheni kwazoizinga lokushisakanye nokusetshenziswa kweukushisa.Njengoba okuqinile kudonsaamandlangesimo sokushisa, izinga lokushisa layo liyakhuphuka, futhi ubukhulu bayo buyanda.Kodwa izinto ezahlukene zisabela ngendlela ehlukile ekusetshenzisweni kokushisa.

Amandla okushisa,ukwanda okushisayo, futhiconductivity ezishisayongokuvamile zibaluleke kakhulu ekusebenziseni izinto eziqinile.

I-Melting Point ye-Duplex Stainless Steel

Indawo encibilikayo yensimbi engagqwali eyi-duplex - SAF 2205 steel icishe ibe ngu-1450°C.

Ngokuvamile, ukuncibilika kuwushintsho lwesigaba sento isuka kokuqinile iye esigabeni esiwuketshezi.Iindawo yokuncibilikakwento izinga lokushisa okwenzeka ngalo lesi sigaba.Iphuzu lokuncibilika liphinde lichaze isimo lapho okuqinile noketshezi kungaba khona ngokulingana.

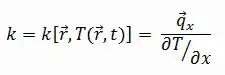

I-Thermal Conductivity ye-Duplex Stainless Steel

I-thermal conductivity ye-duplex stainless steels - SAF 2205 yi-19 W / (m. K).

Izici zokudlulisa ukushisa zezinto eziqinile zikalwa ngendawo ebizwa ngokuthiconductivity ezishisayo, k (noma λ), ikalwa ngo-W/mK Ikala ikhono lento ethile yokudlulisa ukushisa ngento ethileukuqhuba.Qaphela ukuthiUmthetho kaFouriersisebenza kuzo zonke izinto, kungakhathaliseki isimo sazo (okuqinile, uketshezi, noma igesi).Ngakho-ke, kubuye kuchazwe uketshezi namagesi.

Iconductivity ezishisayouketshezi oluningi nezinto eziqinile ziyahlukahluka kuye ngezinga lokushisa, kanti kuma-vapor, kubuye kuncike ekucindezelweni.Ngenjwayelo:

Izinto eziningi ezisetshenziswayo zicishe zifane, ngakho-ke singakwazi ukubhala u-k = k (T).Izincazelo ezifanayo zihlotshaniswa ne-thermal conductivities ku-y- kanye ne-z-directions (ky, kz), kodwa kumpahla ye-isotropic, ukuqhutshwa kwe-thermal kuzimele kusiqondiso sokudlulisa, kx = ky = kz = k.

Isikhathi sokuthumela: Feb-04-2023