Izinto ezilinganiselwe izikhathi zokusebenza

Izinhlelo zokusebenza ezijwayelekile ezidinga izinto eziyi-duplex ukuthi zivezwe ezimeni zokushisa okuphezulu yimikhumbi yokucindezela, ama-fan blades/i-impellers noma ama-exhaust gas scrubber.Izidingo zezakhiwo zezinto ezibonakalayo zingasukela kumandla aphezulu okusebenza kuya ekumelaneni nokugqwala.Ukwakheka kwamakhemikhali kwamabanga okukhulunywe ngawo kulesi sihloko kuhlu kuThebula 1.

Ukubola kwe-Spinodal

Ukubola kwe-Spinodal (okubuye kuqanjwe ngokuthi i-demixing noma ngokomlando njengokuthi 475 °C-embrittlement) kuwuhlobo lokuhlukaniswa kwesigaba esigabeni se-ferritic, okwenzeka emazingeni okushisa angaba ngu-475 °C.Umphumela ophawuleka kakhulu uguquko ku-microstructure, okubangela ukwakheka kwesigaba sika-α´, okuholela ekuhlanganisweni kwezinto.Lokhu-ke, kukhawulela ukusebenza komkhiqizo wokugcina.

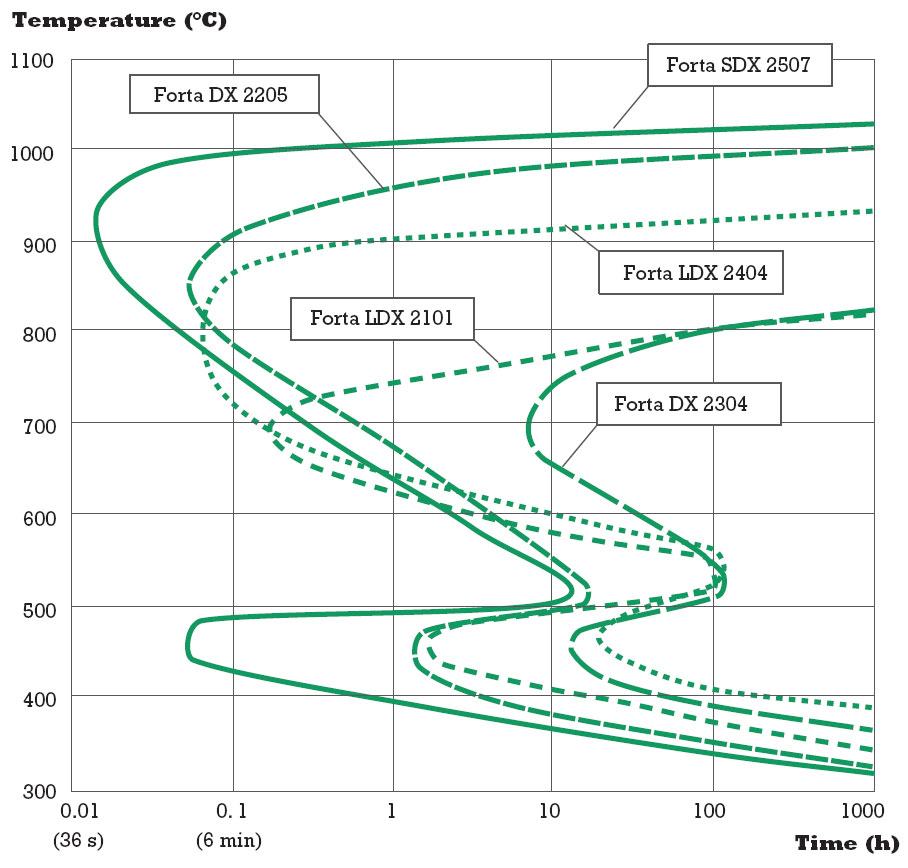

Umfanekiso woku-1 ubonisa umdwebo wenguquko yesikhathi sokushisa (TTT) wezinto eziyiduplex ezifundwayo, nokubola kwe-spinodal emelelwe esifundeni esingu-475 °C.Kufanele kuqashelwe ukuthi lo mdwebo we-TTT umele ukwehla kokuqina ngo-50% okukalwa ngokuhlolwa kokuqina komthelela kumasampula e-Charpy-V, ngokuvamile amukelwa njengebonisa ukuqina.Kwezinye izinhlelo zokusebenza ukwehla okukhulu kokuqina kungase kwamukeleke, okushintsha umumo womdwebo we-TTT.Ngakho-ke, isinqumo sokusetha i-OT ephezulu kakhulu sincike kulokho okubhekwa njengezinga elamukelekayo lokuthobisa okungukuthi ukunciphisa ukuqina komkhiqizo wokugcina.Kufanele kukhulunywe ukuthi ngokomlando amagrafu e-TTT nawo akhiqizwa kusetshenziswa i-threshold ebekiwe, njenge-27J.

Amabanga aphezulu alloyed

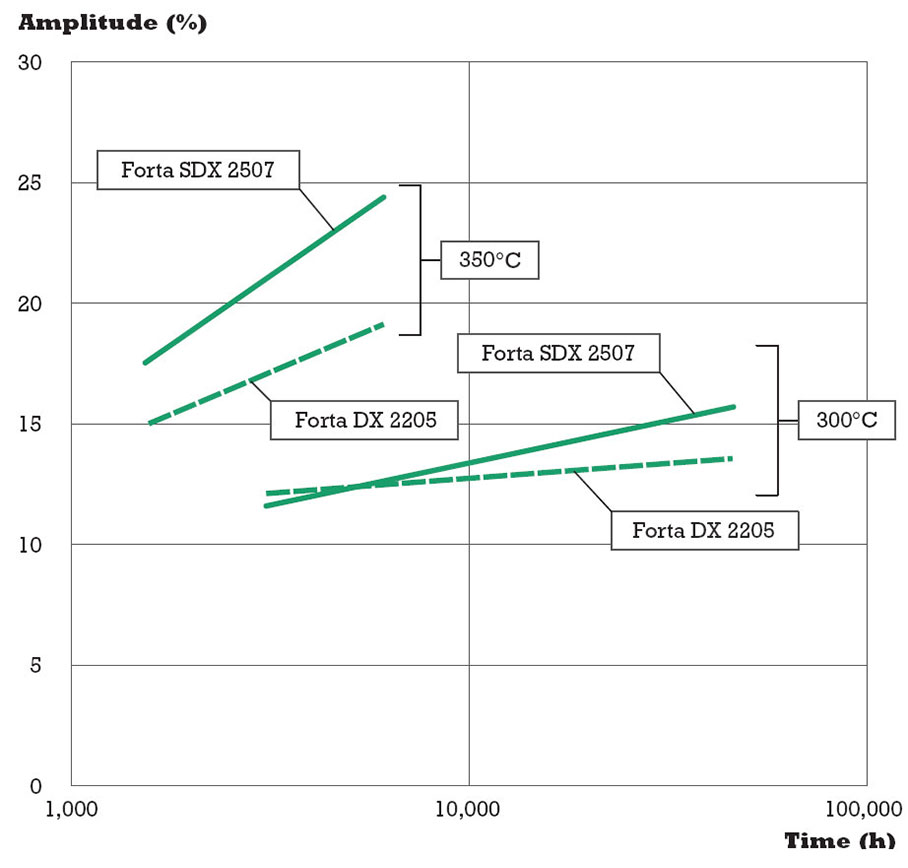

Umfanekiso 1 ubonisa ukuthi ukwanda kwezakhi ze-alloying ukusuka ebangeni le-LDX 2101 ukuya ebangeni le-SDX 2507 kuholela esilinganisweni sokubola ngokushesha, kuyilapho i-lean duplex ikhombisa ukuqala ukubambezeleka kokubola.Umthelela wezakhi ze-alloying ezifana ne-chromium (Cr) ne-nickel (Ni) ekuqhekekeni kwe-spinodal kanye ne-embrittlement kuye kwaboniswa uphenyo lwangaphambilini. inyuswa isuka ku-300 iye ku-350 °C futhi ishesha kakhulu ebangeni eliphezulu lengxubevange ye-SDX 2507 kune-DX 2205 enengxube encane.

Lokhu kuqonda kungabaluleka ekusizeni amakhasimende ukuthi anqume nge-OT ephezulu elungele ibanga lawo elikhethiwe kanye nokusetshenziswa kwawo.

Inquma izinga lokushisa eliphezulu

Njengoba kushiwo ngaphambili, i-OT ephezulu ye-duplex material ingasethwa ngokokwehla okwamukelekayo kokuqina komthelela.Ngokuvamile, i-OT ehambisana nenani lokunciphisa ngo-50% iyamukelwa.

I-OT incike ezingeni lokushisa nesikhathi

Ukuthambekela emisileni yamajika kumdwebo we-TTT kuMfanekiso 1 kubonisa ukuthi ukubola kwe-spinodal akwenzeki kuphela embundwini owodwa wokushisa futhi kuma ngaphansi kwalelo zinga.Kunalokho, kuyinqubo eqhubekayo lapho izinto eziyi-duplex zivezwa emazingeni okushisa angaphansi kuka-475 °C.Nokho kuyacaca futhi ukuthi, ngenxa yamazinga aphansi okusabalalisa, amazinga okushisa aphansi asho ukubola kuzoqala kamuva futhi kuqhubeke kancane kakhulu.Ngakho-ke, ukusebenzisa i-duplex material emazingeni okushisa aphansi kungase kungabangeli izinkinga iminyaka noma amashumi eminyaka.Kodwa okwamanje kunokuthambekela kokusetha i-OT ephezulu ngaphandle kokucabangela isikhathi sokuchayeka.Umbuzo obalulekile uwukuthi iyiphi inhlanganisela yesikhathi sokushisa okufanele isetshenziselwe ukunquma ukuthi kuphephile yini ukusebenzisa into ethile noma cha?U-Herzman et al.10 bafingqa le nkinga kahle: “…Ukusetshenziswa kuzobe sekukhawulelwa emazingeni okushisa lapho i-kinetics yokuhlukanisa i-demixing iphansi kangangokuthi ngeke yenzeke ngesikhathi sempilo yobuchwepheshe eklanyelwe yomkhiqizo…”.

Umthelela we-welding

Iningi lezinhlelo zokusebenza zisebenzisa i-welding ukujoyina izingxenye.Kuyaziwa ukuthi i-weld microstructure kanye ne-chemistry yayo iyahlukahluka kusuka ku-base material 3.Ngokuya ngezinto zokugcwalisa, inqubo yokushisela kanye nemingcele yokushisela, i-microstructure yama-welds ihluke kakhulu kumpahla yobuningi.Isakhiwo esincane ngokuvamile simaholoholo, futhi lokhu kufaka phakathi indawo ethinteke ekushiseni okuphezulu (i-HTHAZ), ethinta ukubola kwe-spinodal kumashisela.Ukwehluka kwe-microstructure phakathi kwenqwaba kanye nokushisela kuyisihloko esibuyekeziwe lapha.

Ifinyeza izici ezikhawulelayo

Izigaba ezedlule ziholela eziphethweni ezilandelayo:

- Zonke izinto ze-duplex zingaphansi

ukubola kwe-spinodal emazingeni okushisa angaba ngu-475 °C. - Kuye ngokuqukethwe kwe-alloying, izinga lokubola okusheshayo noma elihamba kancane lilindelekile.Okuqukethwe kwe-Higher Cr ne-Ni kukhuthaza ukuxutshwa ngokushesha.

- Ukusetha izinga lokushisa eliphezulu lokusebenza:

- Inhlanganisela yesikhathi sokusebenza kanye nezinga lokushisa kufanele kucatshangelwe.

- Izinga elamukelekayo lokuncipha kokuqina, okungukuthi, izinga elifiselekayo lokuqina kokugcina kufanele libekwe - Lapho izingxenye ezengeziwe ze-microstructural, ezifana nama-welds, zethulwa, i-OT ephezulu inqunywa ingxenye ebuthakathaka.

Izindinganiso zomhlaba wonke

Amazinga amaningana aseYurophu naseMelika abuyekezwa le phrojekthi.Bagxile ekusetshenzisweni emikhunjini yokucindezela kanye nezingxenye zamapayipi.Ngokuvamile, umehluko ophathelene ne-OT ephezulu enconyiwe phakathi kwamazinga abuyekeziwe ungahlukaniswa ngombono waseYurophu nowaseMelika.

Izindinganiso zaseYurophu zokucaciswa kwezinto ezibonakalayo zezinsimbi ezingenasici (isb. EN 10028-7, EN 10217-7) zisho i-OT ephezulu engu-250 °C ngokuthi izakhiwo zezinto ezibonakalayo zihlinzekwa kuphela kuze kufike kuleli zinga lokushisa.Ngaphezu kwalokho, izindinganiso zase-Europe zokuklama imikhumbi yengcindezi namapayipi (EN 13445 kanye ne-EN 13480, ngokulandelana) awanikezi noma yiluphi ulwazi mayelana ne-OT ephezulu kulokho okunikezwa kumazinga azo wezinto ezibonakalayo.

Ngokuphambene, ukucaciswa kwezinto zaseMelika (isb. i-ASME SA-240 yesigaba se-ASME II-A) awethuli nhlobo idatha yezinga lokushisa eliphakeme.Le datha esikhundleni salokho inikezwe esigabeni se-ASME II-D, 'Properties', esisekela amakhodi okwakha ajwayelekile emikhumbi yomfutho, isigaba se-ASME VIII-1 kanye ne-VIII-2 (lesi sakamuva sinikeza umzila wokuklama othuthuke kakhulu).Ku-ASME II-D, i-OT ephezulu ishiwo ngokusobala njengo-316 °C kuma-alloys amaningi ayiduplex.

Ngezinhlelo zokusebenza zamapayipi okucindezela, kokubili imithetho yokuklama kanye nezakhiwo ezibonakalayo kunikezwa ku-ASME B31.3.Kule khodi, idatha yomshini inikezwa ama-alloys ayi-duplex afika ku-316 °C ngaphandle kwesitatimende esicacile se-OT ephezulu.Noma kunjalo, ungakwazi ukuhumusha imininingwane ukuze ihambisane nalokho okubhalwe ku-ASME II-D, ngakho-ke, i-OT ephezulu yamazinga aseMelika ezikhathini eziningi ingu-316 °C.

Ngokungeziwe olwazini oluningi lwe-OT, kokubili izindinganiso zaseMelika nezaseYurophu zisikisela ukuthi kunobungozi bokuhlangabezana ne-embrittlement emazingeni okushisa aphakeme (>250 °C) ezikhathini zokuchayeka ezinde, okumele zicatshangelwe kukho kokubili isigaba sokuklama nesesevisi.

Kumashisela, izindinganiso eziningi awenzi noma yiziphi izitatimende eziqinile ngomthelela wokubola kwe-spinodal.Kodwa-ke, amanye amazinga (isb. ASME VIII-1, Ithebula le-UHA 32-4) akhombisa ukuthi kungenzeka ukwenza ukwelapha okukhethekile kwangemuva kokushisela.Lokhu akudingekile futhi akwenqatshelwe, kodwa lapho kwenziwa kufanele kwenziwe ngokuya ngemingcele esethwe ngaphambilini kuzinga.

Okushiwo yimboni

Ulwazi olukhiqizwe abanye abakhiqizi abaningana bensimbi engagqwali eyi-duplex lwabuyekezwa ukuze kubonakale ukuthi bakhuluma ngani mayelana nebanga lokushisa lamabanga abo.I-2205 ilinganiselwe ku-315 °C nge-ATI, kodwa i-Acerinox isetha i-OT yebanga elifanayo ku-250 °C kuphela.Lena imikhawulo ye-OT engenhla nephansi yebanga lika-2205, kuyilapho phakathi kwayo amanye ama-OT axhunywa i-Aperam (300 °C), i-Sandvik (280°C) kanye ne-ArcelorMittal (280 °C).Lokhu kukhombisa ukusabalala kwama-OTs aphezulu aphakanyisiwe ebangeni elilodwa elizoba nezakhiwo eziqhathaniseka kakhulu ukusuka kumkhiqizi kuye kumkhiqizi.

Isizathu sangemuva sokuthi kungani umenzi esethe i-OT ethile ayivezwa njalo.Ezimweni eziningi, lokhu kusekelwe endinganisweni ethile.Amazinga ahlukene axhumana nama-OT ahlukene, yingakho ukusabalala kwamanani.Isiphetho esinengqondo siwukuthi izinkampani zaseMelika zibeka inani eliphakeme ngenxa yezitatimende ezisezingeni le-ASME, kuyilapho izinkampani zaseYurophu zibeka inani eliphansi ngenxa yezinga le-EN.

Adingani amakhasimende?

Ngokuya ngesicelo sokugcina, imithwalo ehlukahlukene kanye nokuvezwa kwezinto ezibonakalayo kulindeleke.Kule phrojekthi, i-embrittlement ngenxa yokubola kwe-spinodal yayithakazelisa kakhulu njengoba isebenza kakhulu emikhunjini yokucindezela.

Kodwa-ke, kunezinhlelo zokusebenza ezahlukahlukene ezidalula amamaki aphindwe kabili emithwalweni ephakathi nendawo kuphela, njengama-scrubbers11–15.Esinye isicelo sasihlobene nama-fan blade nama-impeller, abhekene nemithwalo yokukhathala.Izincwadi zibonisa ukuthi ukubola kwe-spinodal kuziphatha ngendlela ehlukile lapho kufakwa umthwalo wokukhathala15.Kulesi sigaba, kuyacaca ukuthi i-OT ephezulu yalezi zicelo ayikwazi ukusetha ngendlela efanayo nemikhumbi yokucindezela.

Elinye ikilasi lezicelo elezinhlelo zokusebenza ezihlobene nokugqwala kuphela, njengezikhuhla igesi ephuma olwandle.Kulezi zimo, ukumelana nokugqwala kubaluleke kakhulu kunomkhawulo we-OT ngaphansi komthwalo wemishini.Nokho, zombili izici zinomthelela ekusebenzeni komkhiqizo wokugcina, okufanele kucatshangelwe lapho kukhombisa i-OT ephezulu.Nalapha futhi, leli cala lihlukile emacaleni amabili adlule.

Sekukonke, lapho weluleka ikhasimende nge-OT ephezulu efanelekile yebanga labo eliyi-duplex, uhlobo lohlelo lokusebenza lubaluleke kakhulu ekusetheni inani.Lokhu futhi kubonisa inkimbinkimbi yokusetha i-OT eyodwa yebanga, njengoba indawo lapho impahla isetshenziswa inomthelela omkhulu enqubweni ye-embrittlement.

Ingakanani izinga lokushisa eliphezulu lokusebenza kwe-duplex?

Njengoba kushiwo, izinga lokushisa eliphezulu lokusebenza lihlelwe yi-kinetics ephansi kakhulu yokubola kwe-spinodal.Kodwa sikukala kanjani lokhu kushisa futhi ayini ngempela “ama-kinetics aphansi”?Impendulo yombuzo wokuqala ilula.Sesivele sikushilo ukuthi izilinganiso zokuqina ziyenziwa ukulinganisa izinga nenqubekela phambili yokubola.Lokhu kusethwe kumazinga alandelwa abakhiqizi abaningi.

Umbuzo wesibili, kulokho okushiwo yi-kinetics ephansi kanye nenani lapho sibeka khona umngcele wokushisa kuyinkimbinkimbi.Lokhu kungenxa yokuthi izimo zomngcele zezinga lokushisa eliphezulu zihlanganiswa kusukela kokubili izinga lokushisa eliphezulu (T) ngokwalo kanye nesikhathi sokusebenza (t) lapho leli zinga lokushisa ligcinwa khona.Ukuqinisekisa le nhlanganisela ye-Tt, ukuhumusha okuhlukahlukene kokuqina “okuphansi” kungasetshenziswa:

• Umngcele ophansi, obekwe ngokomlando futhi ongasetshenziselwa ukushisela ama-27 Joules (J)

• Ngaphakathi kwamazinga ngokuvamile i-40J ibekwe njengomkhawulo.

• Ukwehla okungu-50% kokuqina kokuqala nakho kuvame ukusetshenziswa ukuze kusethwe umngcele ophansi.

Lokhu kusho ukuthi isitatimende se-OT esiphezulu kufanele sisekelwe okungenani emibonweni emithathu okuvunyelwene ngayo:

• Ukuchayeka kwesikhathi sezinga lokushisa komkhiqizo wokugcina

• Inani eliphansi elamukelekayo lokuqina

• Inkambu yokugcina yesicelo (ikhemikhali kuphela, umthwalo wemishini yebo/cha njll.)

Ulwazi lokuhlola oluhlanganisiwe

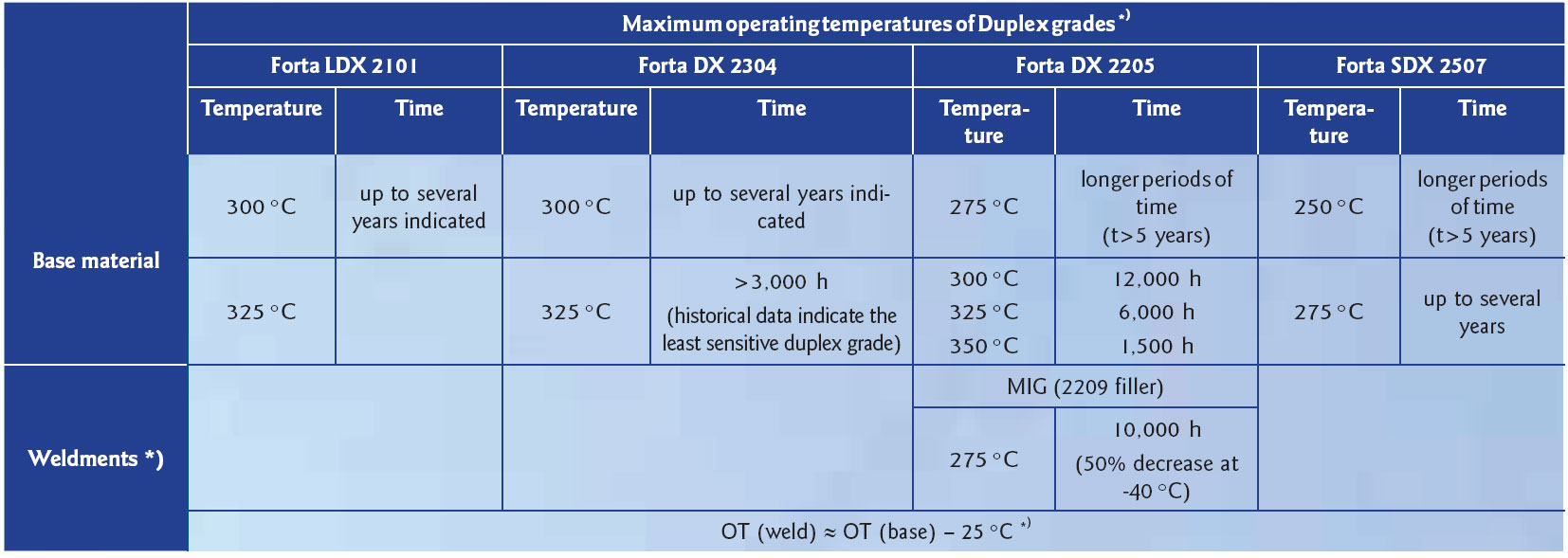

Kulandela inhlolovo ebanzi yedatha yokuhlola kanye namazinga kube nokwenzeka ukuhlanganisa izincomo zamabanga amane aphindwe kabili abuyekezwayo, bheka Ithebula 3. Kufanele kuqashelwe ukuthi idatha eminingi idalwe kusukela ekuhlolweni kwaselabhorethri okwenziwe ngezinyathelo zokushisa ezingu-25 °C. .

Kufanele futhi kuqashelwe ukuthi lezi zincomo zibhekisela okungenani ku-50% wokuqina okusele ku-RT.Lapho kuthebula “isikhathi eside” kuboniswa akukho ukwehla okuphawulekayo ku-RT okuye kwabhalwa phansi.Ngaphezu kwalokho, i-weld ihlolwe kuphela ku -40 °C.Okokugcina, kufanele kuqashelwe ukuthi isikhathi eside sokuchayeka silindelwe i-DX 2304, uma kubhekwa ukuqina kwayo okuphezulu ngemva kwamahora angu-3,000 okuhlolwa.Kodwa-ke, ukuthi ukuchayeka kunganyuswa kangakanani kufanele kuqinisekiswe ngokuhlolwa okwengeziwe.

Kunamaphuzu amathathu abalulekile okufanele uwaqaphele:

• Okutholakele kwamanje kubonisa ukuthi uma amashisela ekhona, i-OT yehla cishe ngo-25 °C.

• Ama-spikes esikhathi esifushane (amashumi amahora ku-T=375 °C) amukelekile ku-DX 2205. Njengoba i-DX 2304 ne-LDX 2101 kungamabanga ahlanganisiwe ahlanganisiwe, ama-spikes ethempelesha esikhathi esifushane aqhathaniswa nawo kufanele kwamukeleke.

• Uma impahla ibolile ngenxa yokubola, ukwelashwa okunciphisa ukushisa ku-550 – 600 °C ku-DX 2205 kanye no-500 °C ku-SDX 2507 ihora elingu-1 kusiza ukubuyisela ukuqina ngo-70%.

Isikhathi sokuthumela: Feb-04-2023